The successful design and development of your tooling is one of the most significant factors that will determine the success of your project. we strive to design tools that are robust in nature, with a focus on minimizing both cycle time and maintenance. We utilize 17 full time mold designers who are proficient in designing injection molds to DME, HASCO, DIN & JIN Meusburge , MISUMI standards.

- Home /

- About Us

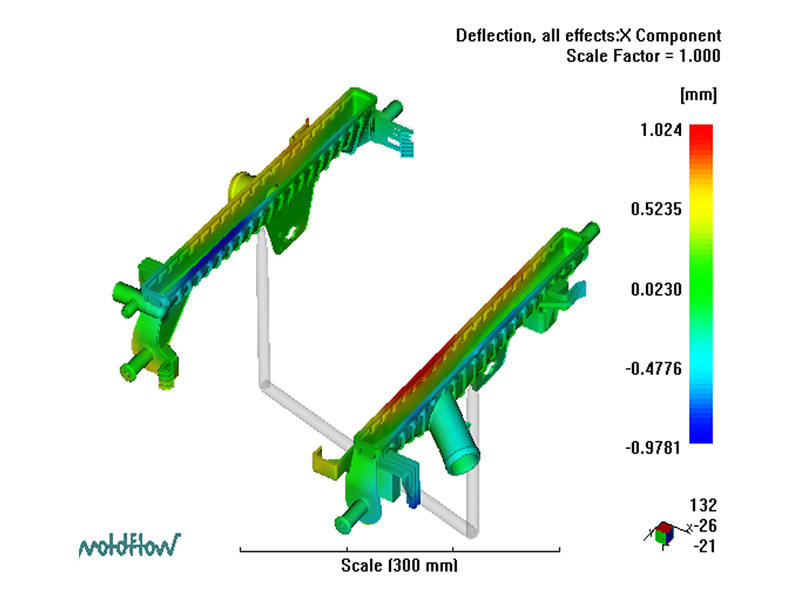

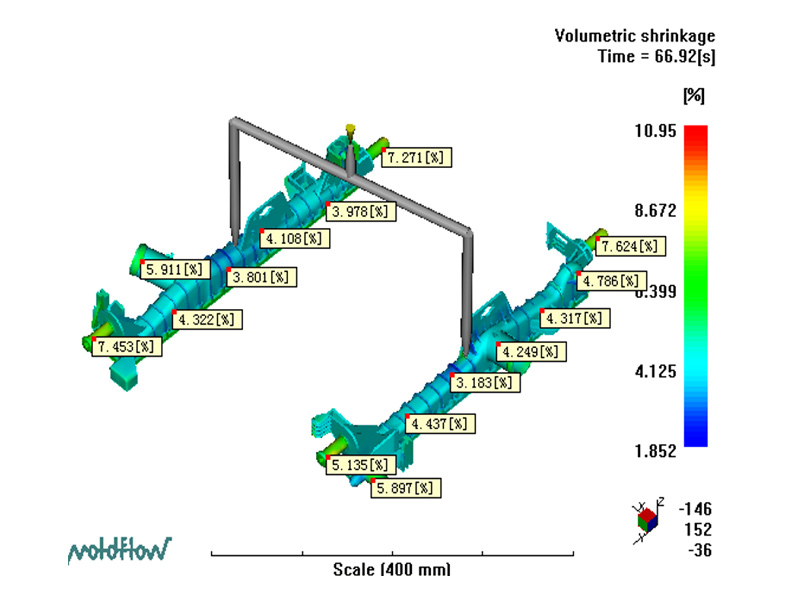

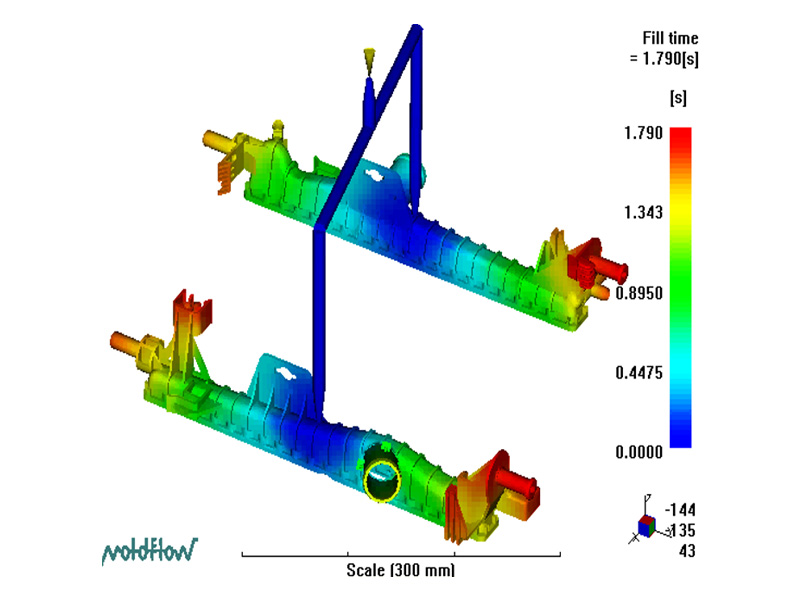

Mold Flow Analysis

We can utilize mold simulation software to quickly check the manufacturability of your plastic part design and manufacturing process and perfect it, before the first piece of steel is cut. We can get rapid feedback on how modifications to wall thickness, gate locations, material or geometry can affect the filling pattern and pressure and temperature distributions in the part cavity. The analysis results and detailed design advice can be used to determine the optimum part thickness and gate locations as well as to identify and eliminate cosmetic issues such as weld lines, air-traps and sink marks. This process reduces the time needed to condition the mold and speeds the product to market.

Mold Design

design and development of your tooling is one of the most significant factors that will determine the success of your project.

We utilize the following software

Auto CAD , Unigraphics CAD/CAM

, Pro/Engineer , Solidworks

Two color Mold

Thin Wall Mold

Multi-cavity MOld

Hot Runner Mold

Unscrewing Mold

Quality Control

We define quality as total customer satisfaction. This drives us to settle for nothing less than for excellence in all aspects of our business as we continuously improve our strong compliment of our staff and processes.

- Mold Base Certificate

- Steel Certificate

- Steel Hardness Report

- Heat Treatment Certificate

- Electrode Inspection Report

- Mold Try-out Report

- Sample Inspection Report

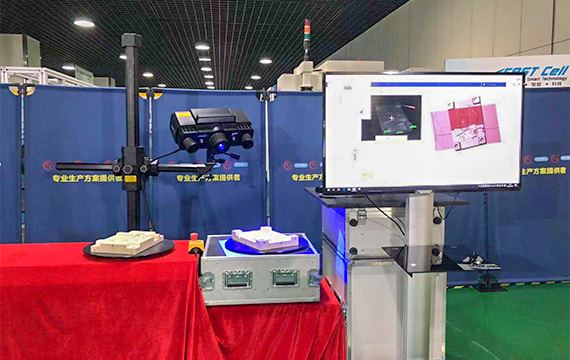

- 3D Scan